Titan 3330™ Real-Time Payload Management System

Give your operators the tools to consistently fill buckets and trucks to target payloads. For wheel loaders and hydraulic excavators.

If your machines are digging without a payload management system, you’re leaving dirt (and money) on the table. Get more out of each pass.

Hello Consistent Payloads

Optimized payloads (the load carried by a piece of machinery) have a big payoff. Even a minor increase in payloads adds up to hundreds of additional tonnes on mining class machines.

Customers using Titan 3330 have seen:

- More trucks loaded to target payload.

- Increased productivity by moving more tonnes in the same number of truck runs.

- Reduced overloads, preventing additional wear on trucks, machine damage, tire wear, fuel use, and spillage.

Move More Dirt in Less Time

Powered by AI

Powerful artificial intelligence continually learns and improves its ability to identify a productive load, bucket by bucket.

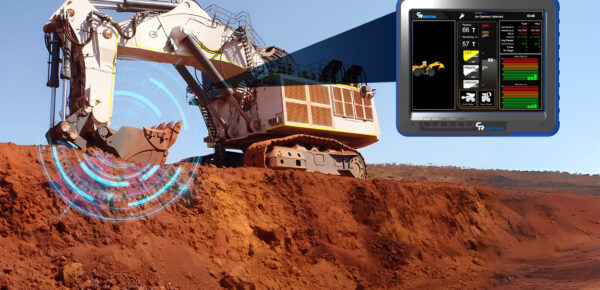

Truck.Trakka Technology

Quickly and accurately identify your haul truck fleet, so target payloads are adjusted and optimized by individual vehicle. Match bucket passes to truck capacity – no more half passes.

Evolved User Experience

You spoke; we listened. We partnered with top operators to develop an upgraded interface that’s intuitive and uncomplicated. Operators get instant feedback in the cab with an easy-to-read display.

Next Generation Payload Monitoring

Digger-based payload weighing gives instantaneous and precise feedback, which is more accurate than truck-based systems. Create a loop of continuous improvement for your operators in the pursuit of filling trucks ever faster and more accurately.

Reduce Your Emissions

Overloaded trucks consume more fuel and require additional maintenance, while underloaded trucks need more passes and fuel to move the same amount of dirt. By optimizing your load and haul circuit, your trucks will make fewer trips while making the most efficient use of fuel, reducing emissions.

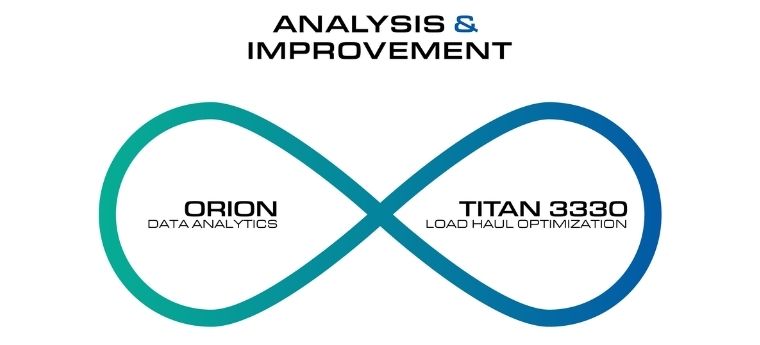

Keep Pushing the Limits of Productivity

Titan 3330 supports your operators with live bucket payload reporting. Supervisions get shift reports via the Orion Data Analytics integration and our Analysis & Improvement service can provide longer-term coaching on bucket payload optimization, so productivity gains compound over time.

Upgrades & Integrations Take You Further

Our dig to plan add-on uses High Precision GPS to provide operators with real-time guidance of bucket tooth position relative to the mine plan and ore boundary. Accepting plans from all leading design packages, with real-time rendering on board for maximum fidelity and user experience. Dig more accurately, with less dilution and more compliance, in any conditions.

Using a fleet management system? With our FMS integration, we can tap into your existing system to automatically sense each truck’s target payload and calibrate accordingly.

Resources

Explore Case Studies

Meet Titan 3330 for Wheel Loaders

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.