Titan 3330™ Minimizes Overloads

Average truck payload increased by 3 tonnes while overloaded trucks decreased by 1%.

Background

Location

Pilbara, Western Australia

Commodity

Iron Ore

Digging Conditions

Hard/Moderate

Machine

Backhoe

Make & Model

Liebherr 996, 996B, R9400

The Challenge

Although the miner was running the latest fleet management systems (FMS), there were a high number of truck overloads each day, causing a bottleneck in production.

The excavator operators lacked confidence in weights reported by the truck payload system due to the variable accuracy and latency, so they weren’t targeting high-capacity loads.

The challenge was to provide an accurate real-time payload management system so operators could increase average truck payloads and maximize productivity without increasing overloads.

The Solution

The Titan 3330 payload management system was installed on the miner’s fleet of Liebherr backhoes.

Titan 3330 provides real-time, pass-by-pass feedback to operators, enabling accurate truck loading while minimizing truck overloads. Sensors fitted on the excavator identify individual bucket cycles and truck payloads. A running summary of each truck and bucket payload is reported live on the Titan 3330 screen.

Operator training on the Titan 3330 system was rolled out once the product was installed and commissioned. CR Digital provided data reporting tools to the customer to monitor the impact of the system.

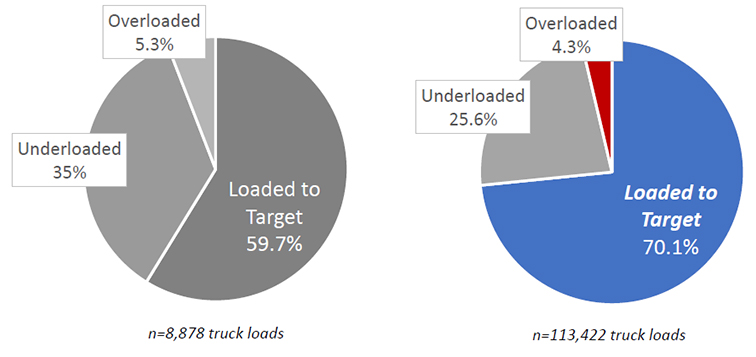

Truck Payload Classification per Period

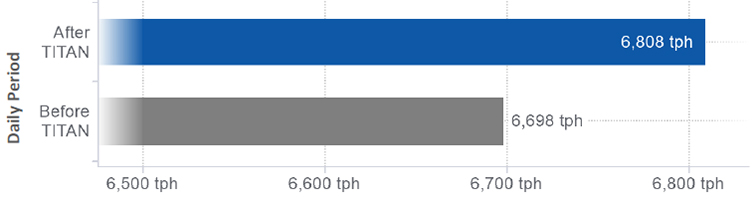

Instant. Production Rate

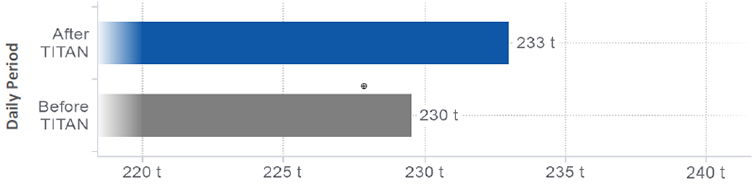

Average truck payload

The Impact

The Titan 3330 payload management system delivered:

- 3 tonne increase to average truck payload

- 18% decrease in overloaded/derated trucks

- 245,000 additional tonnes moved per machine per year

- 28% fewer truck underloads

- 1.6% higher instantaneous productivity*

- 1.4% increase in truck fill factor (compared to truck rated capacity)

- 1.7% decrease in truck payload spread

- 10% reduction in machine attachment duty

*Tramming and idle time not included

THE RESULTS

3

Tonne increase to average truck payload

245000

Additional tonnes moved / machine / year

18

Decrease in overloaded trucks

Explore More Success Stories

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.