Titan 3330™ Increases Production in WA Iron Ore Mine

Operators increased average truck payload while decreasing truck overloads – maximizing productivity.

Background

Location

Pilbara, WA

Commodity

Iron Ore

Digging Conditions

Hard/Moderate

Machine

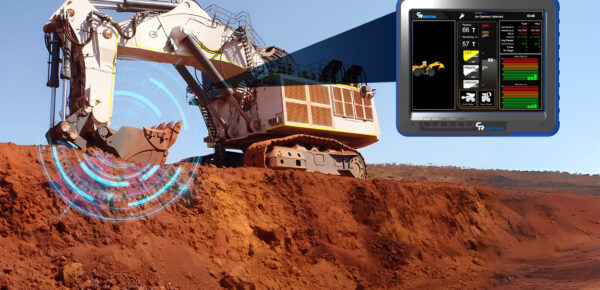

Wheel Loader

Make & Model

Komatsu WA1200

The Challenge

Our customer is an Australian tier one miner based in the Pilbara operating a fleet of wheel loaders and haul trucks in iron ore and waste materials.

The site’s continuous improvement and engineering teams identified an issue with premature tire failures on their Komatsu WA1200 wheel loaders, incurring significant costs in both production and maintenance. The miner created a project charter to reduce general tire wear and early tire failures across the WA1200 fleet while maintaining or improving production rates of their assets.

The site engineering team identified that bucket overloads while hoisting was the primary cause of premature tire failures. They began investigating potential solutions, looking for an advanced technology that could add additional value while solving the problem at hand.

The Solution

The miner selected Titan 3330 as the ideal payload management system to meet its needs. Titan 3330 is designed specifically to provide accurate bucket and truck payloads to operators in real-time.

Real-time feedback on bucket payload enables operators to abort hoisting an overloaded bucket, reducing tire wear and premature failures. It also optimizes the load haul process, increasing fleet production rates.

The system is designed to be intuitive for operators, as well as provide actionable feedback through Orion Data Analytics operator score cards, so every operator can be as good as the best operators.

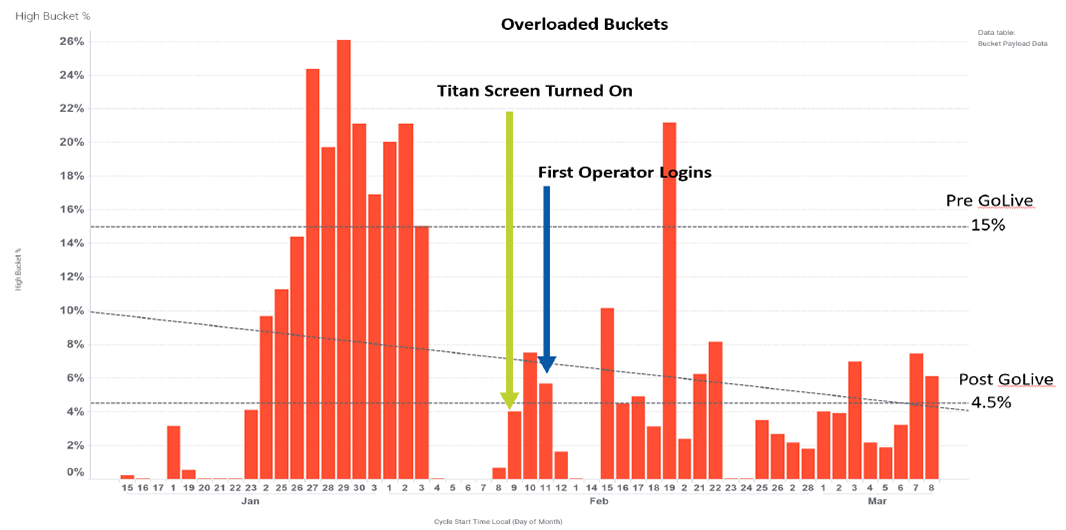

High Bucket Payload % Trending

Decreased bucket overload rate and increased bucket cycle production rate.

The Impact

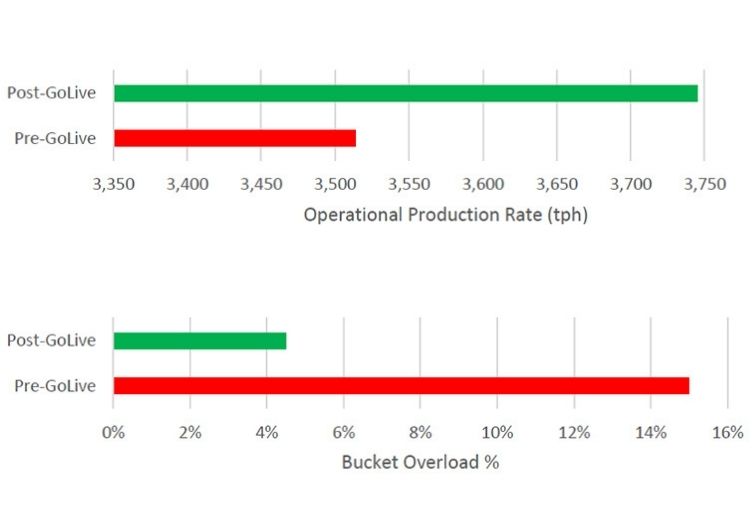

Providing real-time bucket payload feedback and consequently decreasing bucket overload rates can dramatically increase the overall productivity of a wheel loader.

The Titan 3330 payload management system delivered:

-

- 6.6% increase in production per hour

- 506,394 additional tonnes moved per machine per year

- 10.5% fewer bucket overloads

- 14,700 bucket overloads eliminated per year

- 6.6% increase in operational productivity

- 14% reduction in tire damage

- 4.5% decrease in bucket payload spread

THE RESULTS

10.5

Decrease in overloaded buckets

6.67

Increase in operational productivity

14

Reduction in tire damage

4.5

Decrease in bucket payload spread

Explore More Success Stories

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.