Titan 3330™ Monitors Machine Attachment Duty

Titan 3330 reduced machine duty factor by 15%.

Background

Location

Hunter Valley, Australia

Commodity

Coal

Digging Conditions

Moderate

Machine

Backhoe

Make & Model

Liebherr R9800

The Challenge

An Australian mining contractor operating in New South Wales commissioned a new ultra-class mining excavator. A short time into the excavator’s life, signs of overutilization began to emerge. Although the asset was achieving excellent production rates, the miner had no way of quantifying and monitoring machine attachment duty.

The challenge was to record and report duty to both maintenance and production teams, provide a method of self-regulation for operators, and reduce overall machine duty.

The Solution

CR Digital’s experienced field technicians worked with the miner to install Titan 3330 on a Liebherr R9800 backhoe. Titan 3330 can minimize machine duty by providing real-time, pass-by-pass feedback to operators on the major attachments through hydraulic cylinder monitoring.

Sensors fitted on the excavator identify bucket cycles and map hydraulic circuit loads at high frequencies. A duty summary of each bucket cycle is reported live on the Titan 3330 user interface.

Once the system was installed and commissioned, CR Digital rolled out comprehensive operator training on the intuitive system. The miner was provided with Orion Data Analytics to measure the impact.

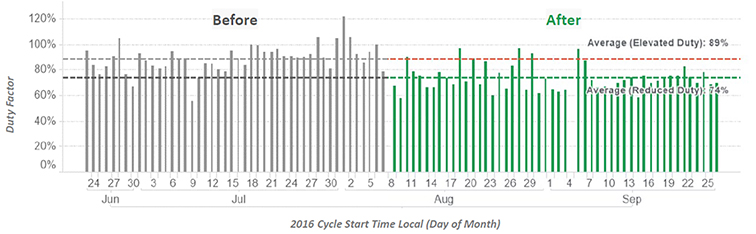

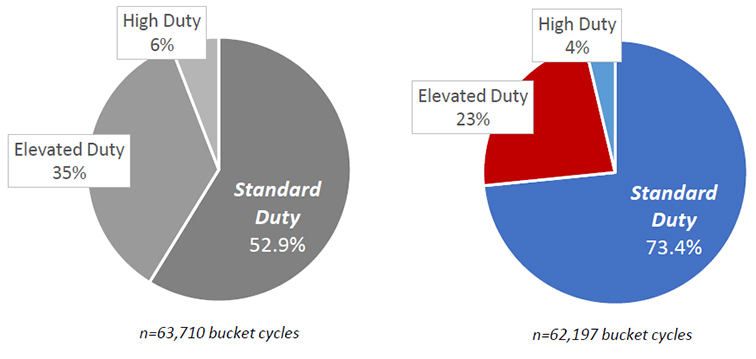

High Duty Factors indicate elevated loads on the excavator attachments and accelerated consumption of machine life.

Duty Cycle Classification per Period

Instant. Production Rate

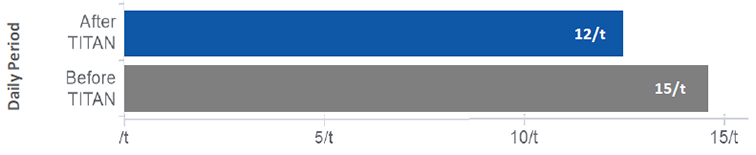

Duty per Tonne

The Impact

Titan 3330 delivered:

- 15% decrease in machine duty factor

- 20% reduction in machine duty per tonne

- 10.5% fewer elevated and high duty events

- 4% fewer truck underloads (equating to an additional 24,000 tonnes of material)

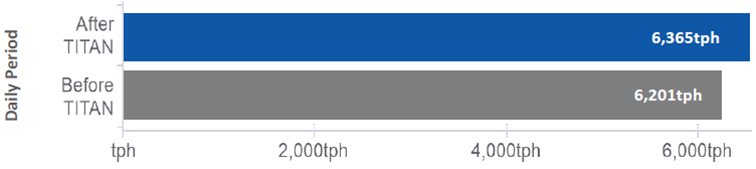

- 2.8% increase in instantaneous productivity*

- 1% higher truck fill factor (compared to truck rated capacity)

- 2% decrease in truck payload standard deviation (falling to 8%)

*Tramming and idle time not included

THE RESULTS

15

Decrease in machine duty factor

20

Reduction in machine duty per Tonne

10.5

Reduction of elevated and high duty events

Explore More Success Stories

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.