GET Trakka™ Stops Costly Crusher Events

GET Trakka provides the ultimate solution to detecting broken and lost GET in real-time.

Background

Location

Namibia, Africa

Commodity

Uranium

Digging Conditions

Hard/Abrasive

Machine

Excavators and Wheel Loaders

Make & Model

PC5550 and CAT994

The Challenge

Our customer, a uranium mine in Namibia, was looking for a GET loss detection system to stop costly crusher events caused by broken GET. They had previously trialed different solutions over the years without much success. They were experiencing an average of 10-12 loss events and 1-2 crusher events per year, causing significant down time. Their machines were using a variety of GET brands.

During previous trials of other GET loss detection technologies, two issues were identified: a high rate of false alarms and the need to track components beyond just teeth. The customer needed a solution that could detect failures of teeth, adapters, and shrouds with a very low false alarm rate.

The Solution

GET Trakka is the only system on the market that could address these challenges.

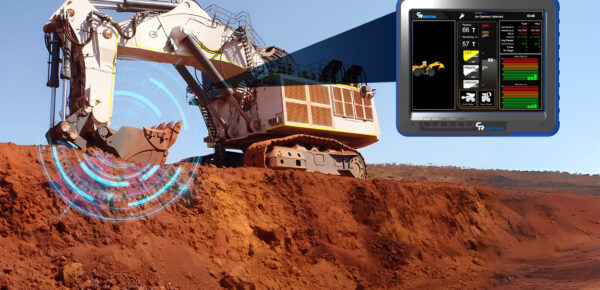

Unlike other solutions, GET Trakka provides both immediate GET loss alarms and the ability to locate lost components on the ground. Using sensors inserted into the GET, it enables real-time detection of lip shroud, wing shroud, adapter, and tooth failures with a reliable alarm system.

GET Trakka identifies all GET loss events in real-time and enables fast and safe location and recovery of broken GET before it gets to the crusher.

Left: Examples of lost or broken GET found on site. Right: Using the portable reader to locate lost GET.

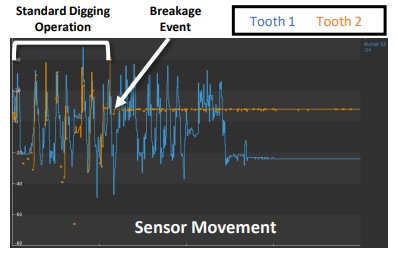

Example of sensor movement graph capturing a breakage event. Tooth 2 is lost and not longer represents a standard digging operation giving accurate times and dates when loss event occurred.

The Outcome

Over 50 Loss Events Recorded

Eliminated Crusher Events

Millions of $ of Cost Savings

The Impact

Over four years of using GET Trakka, the customer saw:

- 52 loss events detected, all located and recovered prior to crusher feed

- Average of 8 losses detected per machine

- 28 tooth and 18 shroud failure events detected

- Reliable, real-time detection and alarming provided to operator

- Operations management team notified via live dashboard alerts

- Thousands of high-risk man-hours eliminated from crusher blockage extraction

- Thousands of hours of throughput capacity protected from unplanned down time

- Regular reports and GET data available to site

- Event log captured and monitored

- Return on investment is realized after one crusher event is prevented

The customer has found CR’s GET Trakka so valuable they no longer want machines operating onsite without it installed. With real-time feedback and reports, reliable alarms, simple and sophisticated sensor design and system install, you can depend on GET Trakka with complete confidence.

Explore More Success Stories

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.