Thunderbird StrataSense Optimizes Drilling

With actionable data on rock hardness, the miner was able to optimize drilling and improve planning.

Background

Location

Chile

Commodity

Copper and Gold

Digging Conditions

High Abrasion

Machine

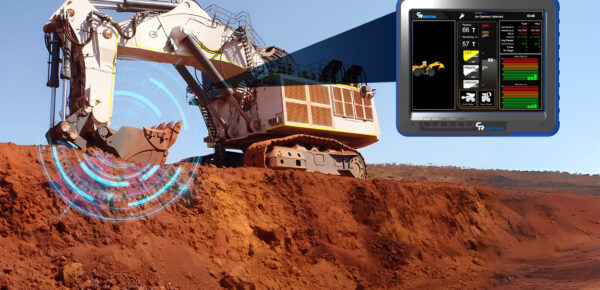

Rotary Blasthole Drill

The Challenge

A Chilean copper and gold miner contacted CR Digital to capture the mechanical energy and steel stress data during the drilling process, identifying the rock hardness of the in-situ rock being dug.

The goal was to generate a geological model of the site with this data, to optimize drilling and blasting configurations and patterns.

The Solution

CR’s Thunderbird high precision GPS system was installed onto three rotary blasthole drills to monitor drilling activity and track penetration rate, torque, pressure, and drill diameter.

The Impact

The rock hardness data provided by the Thunderbird system implemented at the mine are consistent with the geological nature of the in-situ rock and response to stress produced by the drill steel.

With actionable data on rock hardness, the customer improved both daily operation and medium to long-term planning.

The cumulative data of 10,135 holes drilled by the three drills equipped with the Thunderbird system during a 12-month period allowed predictions on the physical response of future material through block models. This enabled the miner to optimize their drilling activities and use different configurations of blasting.

These results empowered the customer to incorporate, with a high level of confidence, the SE parameter as input to the model Hardness in situ reservoir and then to Treatment Model SAG milling (TPH).

Explore More Success Stories

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.