Background

Location

Queensland, Australia

Commodity

Coal

Digging Conditions

Soft to Medium

Machine

Dragline

Make & Model

8200 &2570

The Challenge

Minesites encountered challenges with the removal of existing C-Locks and maintaining the integrity of Surelock locks during rigging operations. These issues led to extended replacement times for rigging components and, in some cases, contributed to unplanned machine downtime due to premature lock failures. Additionally, current rigging locks were not designed for reinstallation once removed.

The Objective

The objective of this initiative was to evaluate whether rigging locks could be successfully refitted, with the potential to reduce operational delays and deliver measurable cost savings for customers.

The Solution

CR reviewed the problems with the existing C-Lock design and updated the clip mechanism in the nut to enable easier removal without the threat of premature failures. Trial parts of the new design were supplied to 2x Queensland coal sites to trial over a 6-8 month period. Key achievements to observe were:

- Locks are easy ot install and remove with existing tools available

- Locks could be refitted multiple times without losing retainer integrity

- Locks would reach the life of the rigging part is was fitted to.

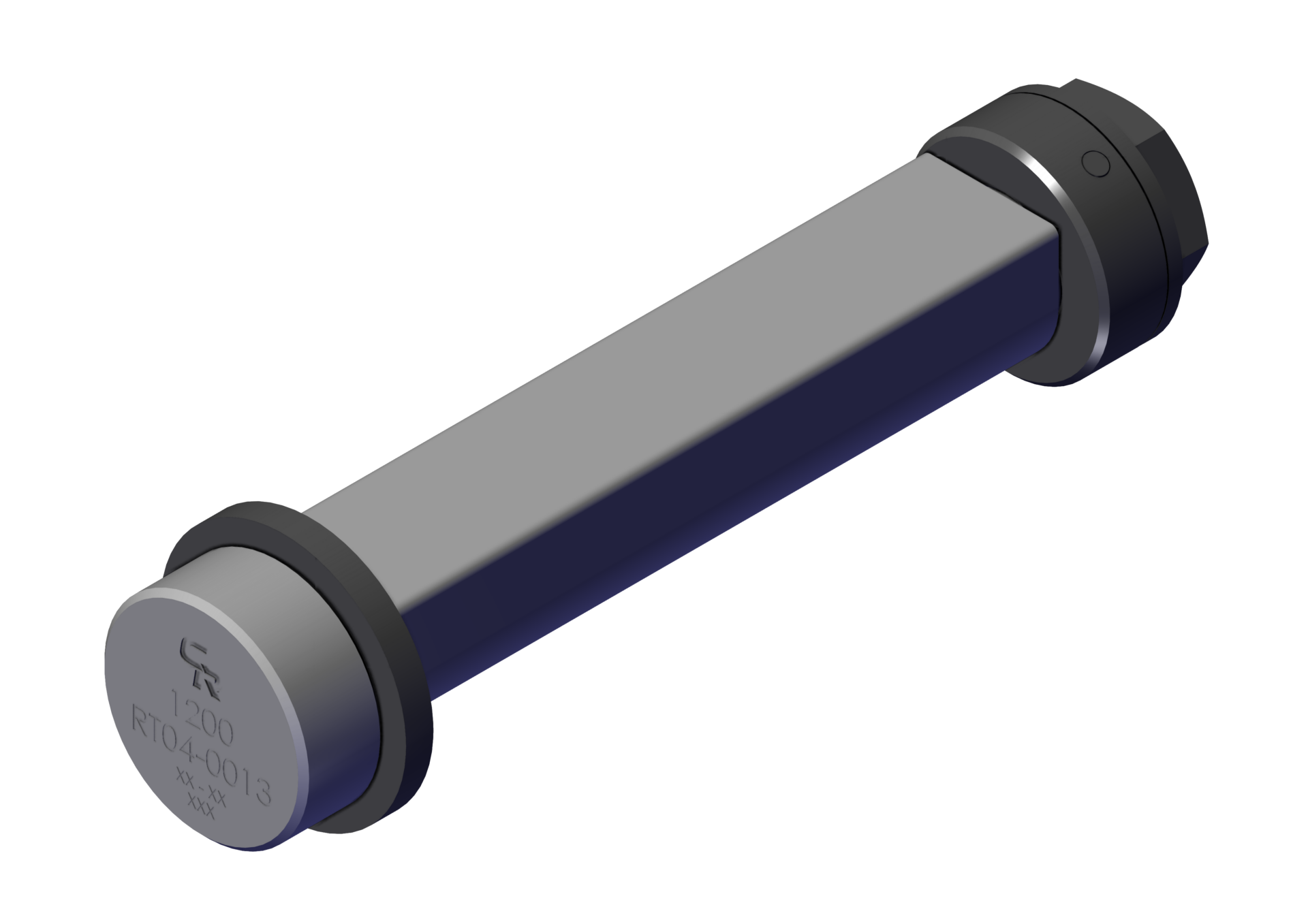

Figure 1 – CR C2-Lock.

The Impact

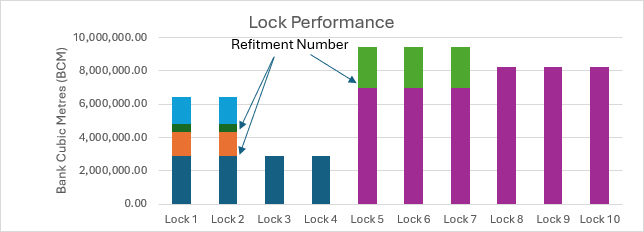

Both Queensland coal sites were happy with the performance of C2-Locks over existing C-locks and Surelocks. The below table shows a number of locks fitted at both sites and their total BCM’s achieved while also tracking how many times locks were refitted and the BCM’s achieved at each refitment. Locks 1-4 were fitted on site 1 and locks 5-10 were fitted on site 2.

Figure 2 – lock performance report after refitment with CR C2-Locks.

Key Observations

Locks were able to be re-fitted up to 3 times. The third time was a test to see how far the locks could go. CR recommends

a limit of 2 refits to ensure lock integrity is maintained. (Refitments were triggered by rigging part replacements, not because of the lock itself). Lock total BCM’s reached a total of

- Site 1 – 6.4M BCM’s

- Site 2 – 9.4M BCM’s

- Locks were easy to install and remove. Sites reported they were often able to remove the locks with hand tools instead of power tools which can significantly reduce safety risks during maintenance events.

- Locks 3, 4, 8, 9 & 10 were not refitted due to maintenance teams throwing out the lock before it could be refitted. (A communication gap between shift changes)

- Locks lasted the life of the rigging part they were fitted to.

Customers wanted to continue using C2-Locks at the completion of the trial for all rigging parts.

Re-fitting locks can reduce the amount of locks used and as a result can offer cost savings.

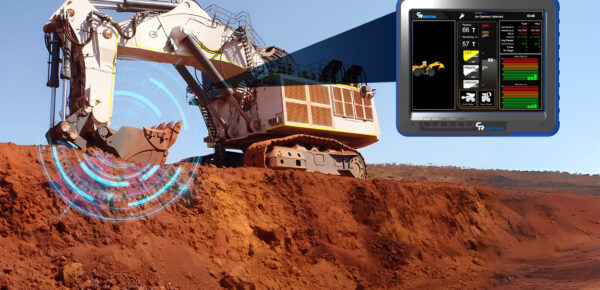

Figure 3 – CR C2-Lock installation in dragline rigging.

Explore More Success Stories

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.