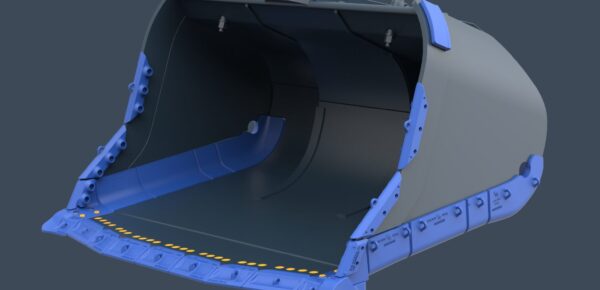

Wearpact™ Continuous Edge GET System

Developed for extended wear life, even in the harshest conditions.

Wearpact is the premium continuous edge GET system built for both underground mining and surface material handling, suitable for any material and loading conditions.

Simple and Safe System

The continuous edge GET is engineered to drive maximum performance and wear life, while reducing safety risks associated with working under buckets. Designed for underground LHD applications and medium-sized wheel loaders in mining and quarry applications.

Product Features

Wear Indicators

Wear indicators in the shroud make it easy to see when they need replacing, taking the guesswork out of maintenance monitoring.

Self-Sharpening

Edges are designed to wear from the bottom up, so clean up stays precise all the way to end of life.

Reliable & Easy Locking

Our patented wedge nut system keeps components on securely, while being easy to install and remove.

Safety First

Working underneath a bucket is risky business, putting workers at risk of having hands and limbs cut or crushed. With Wearpact, shrouds are bolted from the top of the lip, so there’s no need to work underneath the bucket. The top locking mechanism eliminates hammers and hot work, two other higher-risk activities.

Built Tough to Cut Down on Maintenance

Removing gaps between the shrouds and protecting bucket corners provides unparalleled wear protection, so your buckets will spend less time in the shop. The result? Higher machine availability and reliability. The hard-wearing steel improves wear life, while the protected bucket corners also reduce material spillage.

The Digging is Easy

The continuous edge and low-profile lip produces a clean cut, moving dirt more efficiently and reducing stress on the machine. The design places wear material only where it’s needed (underneath the lip), so you’re not paying for steel that’s not required.

A ROM Clearing Powerhouse

Wearpact is the right choice for surface applications like ROM pad work or loading road trains and crushers. Rogue stones can do serious damage to truck and loader tires, causing production delays and expensive unplanned maintenance. With the right lip on your wheel loader, you can ensure the ROM pad is kept clear and operations continue as planned.

Suits Front End Loader Machines

| Epiroc | ST7 – ST18 |

| CAT | R1300 – R3000 |

| Sandvik | LH307 – LH621 |

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.