Titan 3330™ Pass Matching

After data analysis, an operator mentoring program was put in place to optimize loading practices, increasing productivity.

Background

Location

Central QLD, Australia

Commodity

Coal

Digging Conditions

Moderate

Machine

Backhoe

Make & Model

CAT 6040

The Challenge

A coal miner in Central Queensland saw continuous production improvements for the initial six months after installing Titan 3330 on their machine. After that point, production rates started to plateau, creating a challenge for both the CR Digital Analysis and Improvement (A&I) team and the miner to drive further advances.

The challenge was understanding the bottlenecks within the load haul circuit and implementing a plan to increase production to even higher levels.

The Solution

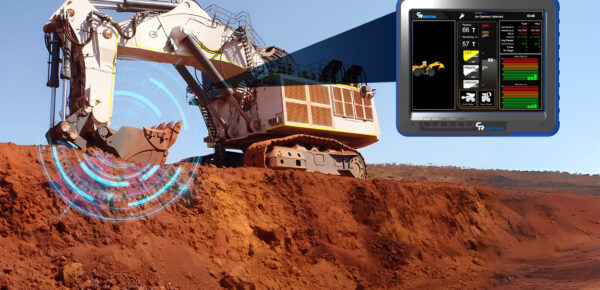

The A&I team worked with the miner to unleash the full benefits of the data collected by the Titan 3330 payload management system installed on their CAT 6040 backhoe.

After crunching the numbers via Orion Data Analytics, the team identified two areas for improvement.

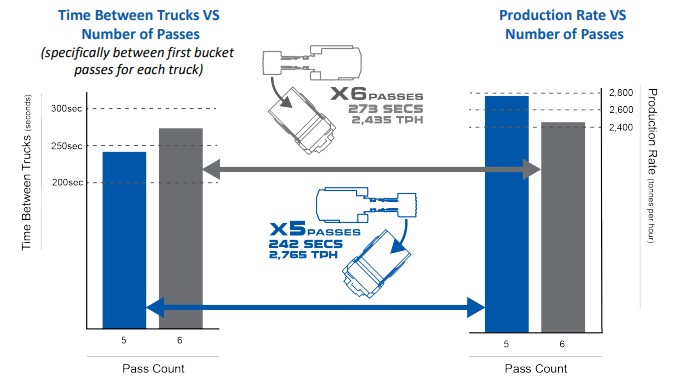

A pass matching analysis discovered that operators were performing six bucket passes, where the last pass was typically a partial bucket. Partial bucket passes extend truck fill times while underutilizing bucket capacity, decreasing the overall production rate.

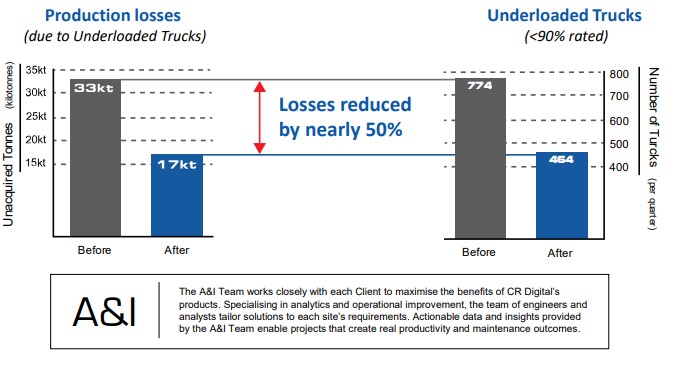

The team also analyzed truck loading data and found that a significant portion of trucks weren’t loaded to full capacity, leaving critical tonnes of material in the bench.

These insights were shared with site trainers to build a mentoring program to help operators optimize loading practices. The result was a reduction in underloaded trucks per shift and higher production.

Optimized pass matching through Titan 3330’s real-time feedback and A&I insights delivered a 2.5% increase in instantaneous production rate (on top of initial production increased unlocked after installation).

Truck loading data analysis and a subsequent operator mentoring program delivered a 6.2% reduction of truck underloads, equating to an additional 16,000 tonnes of material moved during a single quarter.

The Outcome

Increased Operational Productivity

Increased Truck Fill Factor

Reduced Major and Minor Truck Overloads

The Impact

Combined with operator mentoring, Titan 3330 delivered:

- 19.5% higher operational productivity

- 2.5% increase in instantaneous productivity*

- 2% more truck fill factor (compared to truck rated capacity)

- 1.5% fewer truck minor overloads (>110% rated capacity)

- 0.2% reduction of truck major overloads (>120% rated capacity)

*Tramming and idle time not included

THE RESULTS

19.5

Increase in Operational Productivity

2

Increase in Truck Fill Factor

1.5

Fewer Truck Minor Overloads

0.2

Fewer Truck Major Overloads

Explore More Success Stories

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.