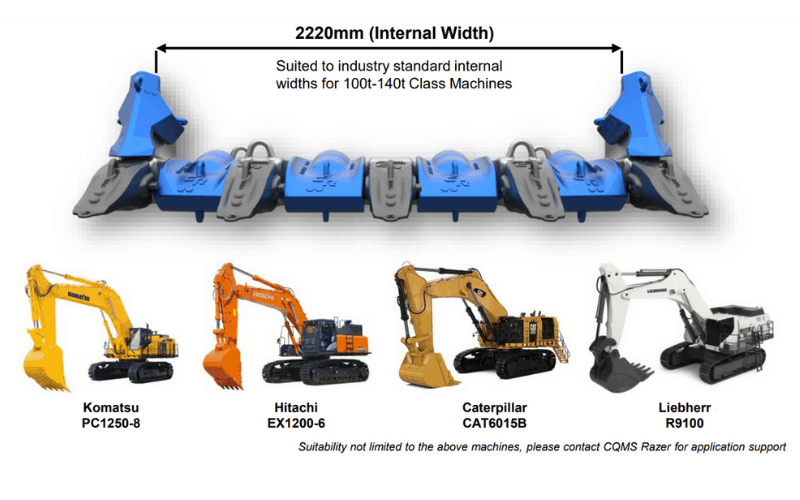

CR has expanded its world-class range of cast lip solutions with the addition of the new RE1522 cast lip for 100t-140t class machines.

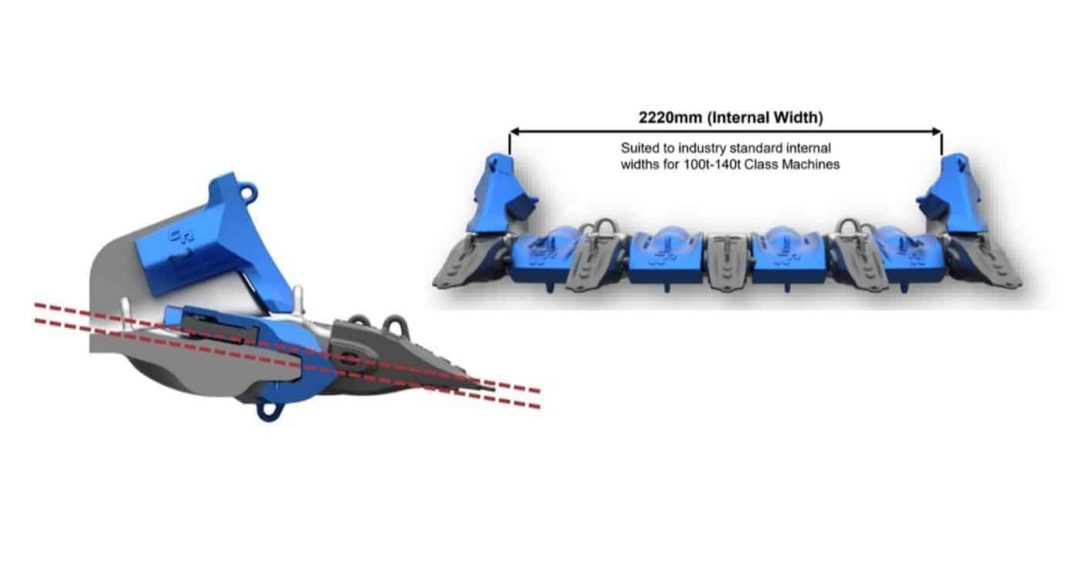

The RE1522 is part of the RazerEdgeTM cast lip solution range and is the smallest cast lip ever designed by CR.

The RE1522 boasts superior strength increases over conventional plate lip installation and provides increased reliability with significant improvements in maintenance and associated down time related to GET change outs.

Lips designed for smaller machines

Quintin Nienaber CR GM Category Management – Surface Mining said the RE1522 had been designed in response to customer requests for their high-quality products across smaller machine applications.

“CR cast lips have built a reputation as the lightest and strongest available in the market delivering improved performance across a variety of commodities in Australia and overseas,” said Mr Nienaber.

“The RE1522 combines our trusted cast lip market experience with a new innovative design for smaller class machine applications, offering our customers greater opportunities for improved productivity across the breadth of their operations.

“Whether our customers are targeting increased productivity, increased utilization, improved cycle times, or optimized fill factors, with our expert advice and support network, they can be sure our cast lip solutions are the right choice,” said Mr Nienaber.

The benefits of cast lip solutions

The RE1522 single piece cast lip design removes excessive heat affected zones, sharp transitions, and uncontrolled weld stresses by eliminating them altogether. The design significantly reduces risks associated with G.E.T. change outs and improves maintenance practices by eliminating requirements for hot work on continual repair welds.

CR Cast Lip systems are designed at our Technology Park in Australia, and manufactured globally.

Learn more about our cast lip systems.