Brisbane, Australia: CR Powered by Epiroc, a leading engineering, productivity, safety, and sustainability partner for mining operations, celebrates the delivery of their 300th dragline bucket to the Stanmore South Walker Creek mine and supports the local Aboriginal and Torres Strait Islander Health Services in Mackay.

Founded in Mackay in 1979, CR Powered by Epiroc (known formerly as CQMS Razer) has been a long-trusted partner in the mining industry in Australia and globally. With its ethos deep-rooted in innovation and unrivalled customer service, CR has disrupted the dragline industry by developing an advanced bucket design that quickly became first-in-class in its category.

Initially supplying the industry with dragline teeth, adaptors, and rigging, CR expanded to dragline buckets in 1998 with the launch of the EarthEater. Listening to their customers and the industry’s ever-evolving needs, by 2006, CR launched the first-generation Hurricane™ bucket with an innovative design that significantly increased fill factor and productivity.

By 2016, the bucket design had evolved to Hurricane 2.0, pushing the limits of high production even further. With a lower profile and a wider front ring, the bucket increased productivity gains by over 16% compared to conventional dragline buckets. The bucket fill factor had also increased by up to 130%. It is no surprise that nine out of ten draglines in Australia are fitted with a CR bucket.

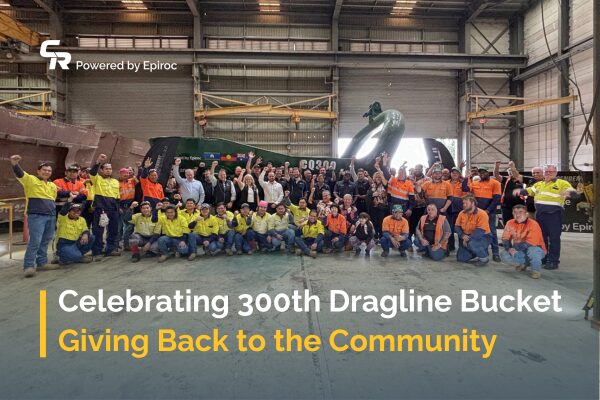

Fast forward to 45 years later, CR is about to deliver its 300th dragline bucket (CQ300) to the Stanmore South Walker Creek mine. “It is a privilege to share this milestone with Stanmore South Walker Creek; this is quite a special moment for CR Powered by Epiroc as South Walker Creek was the first to purchase the hurricane-style bucket. In addition, the relationship we have with our suppliers enables us to deliver world-class products to valuable customers”. says Miguel Guimaraes, Head of East Australasia and India for CR Powered by Epiroc.

Jason Greig, General Manager Operations & SSE for South Walker Creek Mine, highlighted the significance of this milestone stating. “The 300th dragline bucket symbolizes not just a remarkable achievement in engineering, but also the collaborative spirit that is so prominent in our industry. Stanmore’s South Walker Creek Mine is privileged to be the recipient of the industry leading 300th dragline bucket, and we look forward to the continuation of the significant capabilities the hurricane bucket has been bringing to the South Walker Creek operation for the past 20 years”.

Marking this significant milestone, CR has joined forces with industry partners, including Stanmore, IMS, Bisalloy steels, SunCity Signs, Centurion, iScope, INDT and RPG Australia, to support the local communities. Together, they have raised $60,000 for ATSICHS—Aboriginal and Torres Strait Islander Health Services in Mackay—a local not-for-profit organisation committed to providing holistic health care to Aboriginal and Torres Strait Islander people in the region. Alongside the donation, the celebration raises awareness for this important cause. Miguel adds, “CQ300 is an exciting milestone for CR powered by Epiroc. This allows us to celebrate a fantastic charity in ATSICHS and the amazing work they do for the Mackay region”. Valerie Pilcher, Executive Manager for ATSICHS, adds, “The funding will support all areas of our organisation, including continued support of our school programs, community events to promote and provide education around health and wellbeing and improving the understanding of health risks that our First Nations people experience every day of their lives”.

Through collaboration and innovation, this milestone signifies a significant achievement of CR’s strong commitment to customer excellence. It also serves as a testament to the positive impact that collaborative efforts can exert on local communities.

For more information please contact:

Jessica Moor, Digital Marketing & Communications Specialist

+61 4 4860 0979

marketing@crmining.com

CR Powered by Epiroc engineers advanced mining products and digital solutions for surface and underground mining equipment. Its advanced physical and digital solutions help the world’s best miners unlock productivity, enhance safety, and reduce emissions. Backed by a stringent design process, data-based testing protocol, and passionate engineers with decades of experience, they are the next generation of mining technology that enables customers to link actionable data with operational decisions that deliver on sustainability and performance ambitions. Learn more at www.crmining.com.