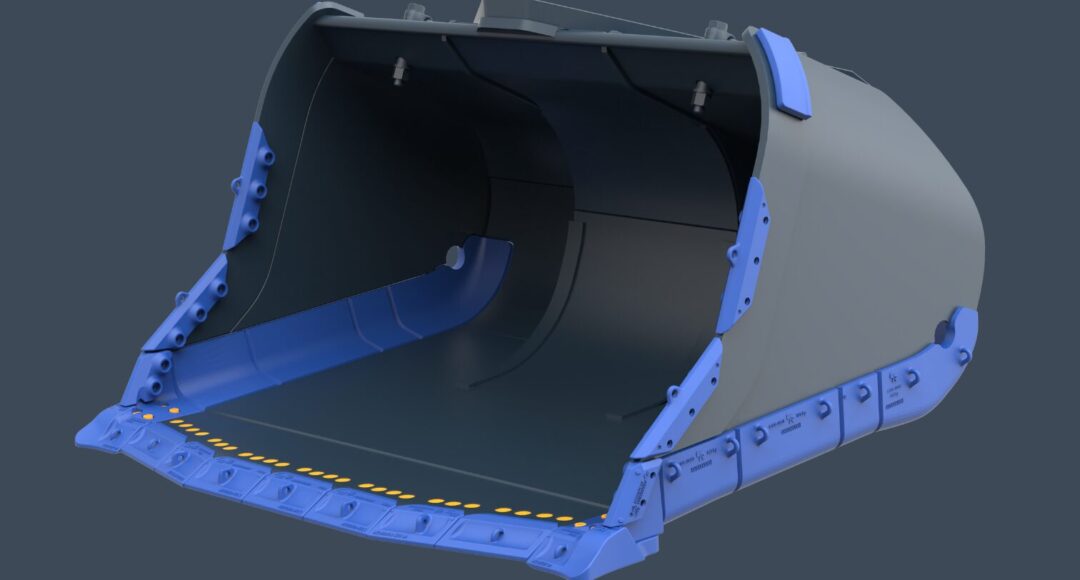

World-Class Underground LHD Bucket

Standard and heavy duty buckets available for most LHD models.

Buckets for LHDs (Load Haul Dump) designed and engineered to reduce maintenance and increased production.

Product Features

Cast Top Corners

Cast top corners reduce the risk of damage to underground utilities and support, with the added benefit of increasing the bulkhead strength of the bucket.

Radius Top Corners

High-quality alloy castings in corners mean no mechanic or weld-on heel blocks.

High-Quality Alloy

Simplifies maintenance by removing bucket features that create additional costs and optimizing material selection and placement.

Built with Safety in Mind

CR’s LHD buckets are designed to focus on safety and durability to meet the demands of underground mining operations. By reducing the excess protective material on the bucket, we have made maintenance more straightforward and extended the lifespan of the equipment.

Innovative, High-Quality Alloy

Our alloy has been extensively tested in all possible underground conditions, and we are proud to say that it has no match in the industry. The result is a bucket that provides the highest possible machine up time for LHDs, giving miners the peace of mind they need to focus on their operations and achieve their goals. We work closely with our clients to understand their requirements and provide customized alloy solutions that are both efficient and cost-effective.

CR’s Underground GET Systems

We offer industry-leading LHD (Load Haul Dump loader) lip systems that enhance the productivity and safety of your buckets. These advanced systems improve the wear resistance of the bucket lips, reducing the frequency of replacements and the associated down time. In addition, our LHD lips have been designed with improved penetration, allowing for more efficient digging and loading.

Maintenance-Reducing Cast Corners

Bottom cast corners eliminate the need for costly heel shrouds and related maintenance, extending loader bucket life by preserving its structure. Crafted from CR’s wear-resistant alloy, our corners offer a high performance-to-weight ratio. Compatible with Cat R2900, Cat R3000, Epiroc ST18, and Sandvik LH621.

Calculate your potential maintenance savings with our cast corners

Qty / year | Price ($) | Hours | Total / year | |

Heel Shrouds | 10000 | |||

Labor + consumables | 6600 | |||

Total estimated savings per year | 16600 |

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.