Welcome to MINEXCHANGE 2025

We are excited to showcase our innovative products and solutions and how we at CR Powered by Epiroc set new standards of performance in the mining industry. Visit us at MINEXCHANGE 2025, where we join industry leaders to learn, connect, and innovate on today’s critical topics, from cutting-edge technology to responsible mining.

From February 23 – 26, you will find us at the Epiroc booth #1401, showcasing our advanced lips, GET systems for surface and underground operations, digital solutions, and reliable service support—all engineered to empower you to stay safe, mine smart, and drive sustainable mining forward.

Information at a glance

| Date | February 23, 2025 – February 26, 2025 |

| Location | Denver, Colorado |

| Country | United States of America |

| Venue | Colorado Convention Center |

| Sunday February 23 – Wednesday February 26 | 7:00 am to 5:00 pm |

Our underground offering at display

Built for performance, our advanced lips, GET systems, and buckets maximize efficiency and durability for underground loaders. Our solutions enhance safety, extend wear life, and optimize operations in the toughest conditions.

With innovative engineering and reliable support, we help you mine smarter, safer, and more sustainably.

Wearpact

Continuous edge lip for wheel loaders and LHDs for extended wear life, even in the harshest conditions.

SNRG

Retrofit bolt-on lip for popular OEM underground mining Load Haul Dump (LHD) loaders.

Armourblade

A weld-on, low-profile, high-penetration bucket edge system for underground mining Load Haul Dump (LHD) loaders.

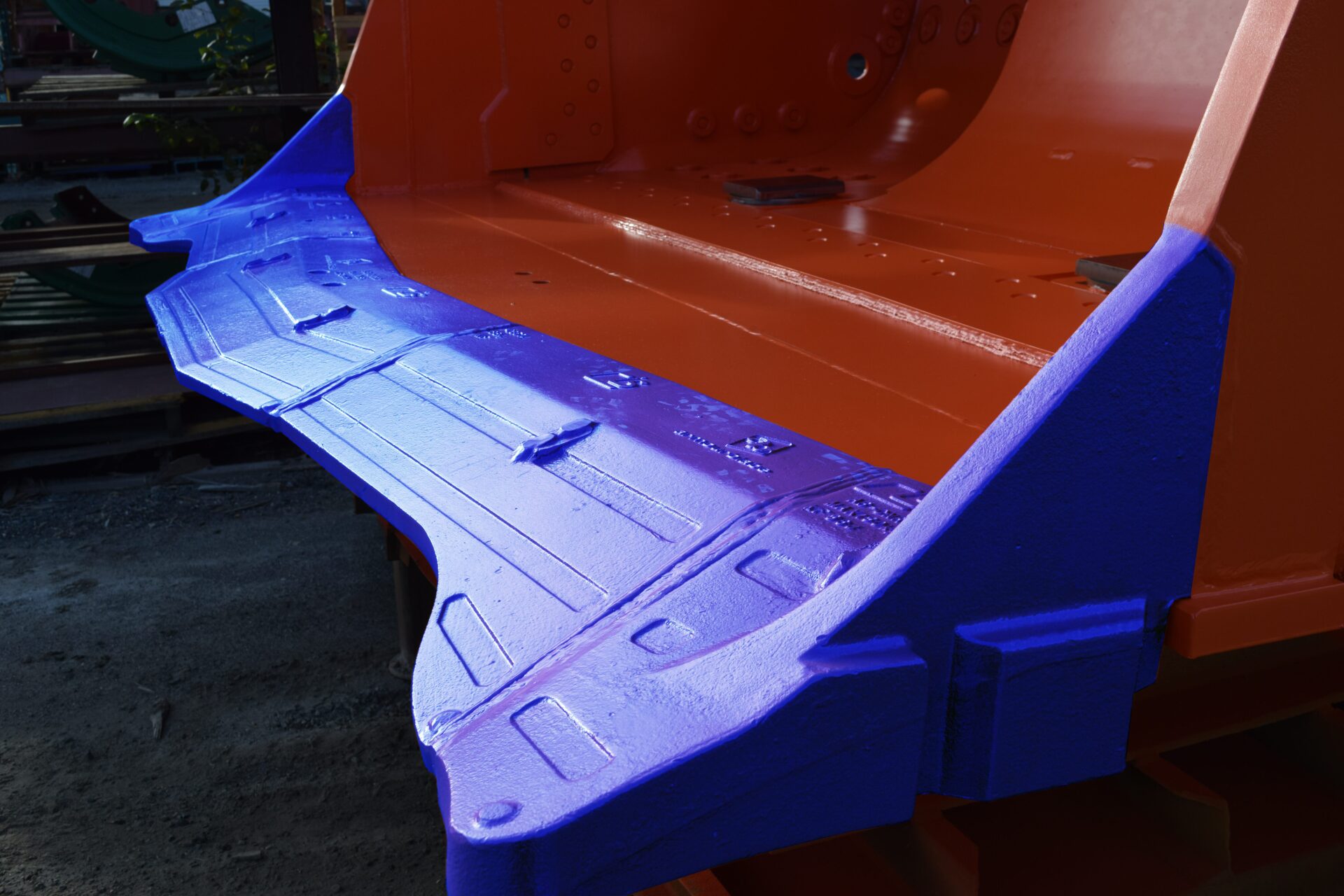

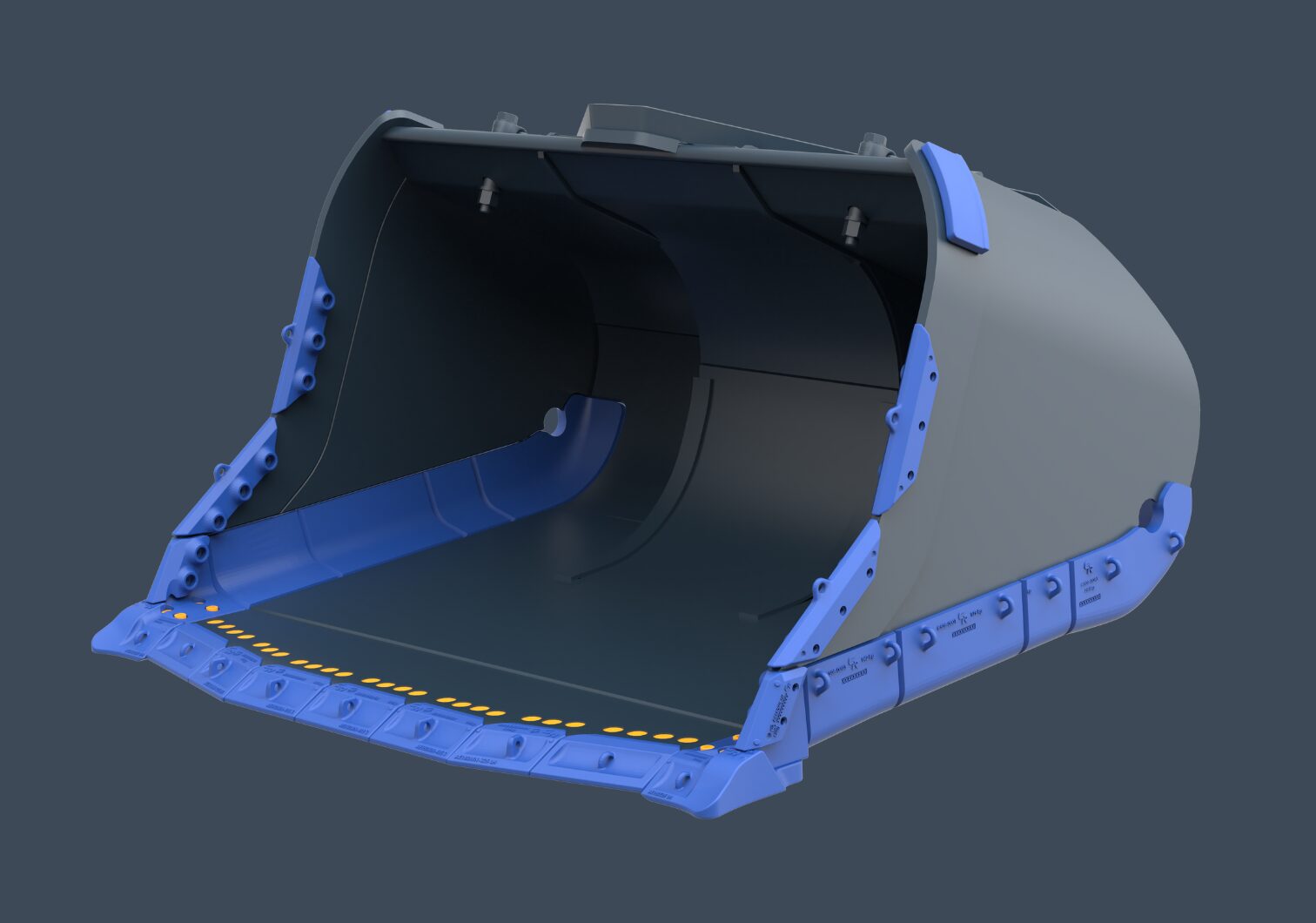

LHD Bucket

Buckets for LHDs (Load Haul Dump) designed and engineered to reduce maintenance and increased production.

Our digitalization offering

CR Powered by Epiroc’s cutting-edge digital solutions are engineered to enhance safety, productivity, and sustainability. Our technology integrates payload monitoring, GET loss detection, and data analytics, giving you real-time actionable insights for more intelligent, data-driven decision-making.

GET Trakka

Real-time GET (Ground Engaging Tools) detection (teeth and shrouds) for wheel loaders, hydraulic excavators (backhoes and face shovels), and electric rope shovels.

Analysis & Improvement

More than data. Our experienced analysts provide operational insights to make real improvements to your mine’s performance.

Our surface offering at display

We engineer high-performance ground engaging tools (GET) and lips for rope shovels, hydraulic excavators, and wheel loaders to maximize productivity and durability. Our solutions enhance safety, extend wear life, and reduce maintenance demands in the toughest mining environments.

With cutting-edge design and data-driven insights, we help you mine smarter, safer, and more efficiently.

SaberEdge

Save up to 400 hours of maintenance per bucket rebuild compared to traditional rope shovel lip systems.

DipperEdge

Prolifically productive cast lips to reduce your Total Cost of Ownership (TCO).

TLC

No more stress cracks – eliminating hot work stops heat-affected zones from forming and creating weak points.

Stingray

Our Stingray™ and RazerEdge™ cast lips are engineered to make mining excavators from 100t to 1000+ prolifically productive.

Why CR Powered by Epiroc?

We Know Mining

After 40+ years serving miners exclusively, we GET you, from common challenges to operational priorities.

We Work Closely With You

We’re on the ground with you, always looking for improvements, solving problems, and supporting you every step of the way to greater productivity.

We’re Passionate Innovators

We never stop on our mission to develop the most advanced solutions in the world. We use cutting-edge technologies like FEA and scale testing to precision engineer every centimeter.

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.