Super Penetrator Boxpoints

The new boxpoints reduced truck fill time by an average of up to 7 seconds.

Background

Location

Hunter Valley, NSW

Commodity

Coal

Digging Conditions

Medium Impact/Medium Abrasion

Machine

Excavator

Make & Model

R996

The Challenge

A prominent Hunter Valley Coal mine wanted to trial new ground engaging tools with the aim of improving their excavator performance by optimising digging productivity and penetration profiles. CR worked with the Mine operator to provide the solution.

The Solution

CR Mining’s experienced field technicians and engineers, worked with the Mine operator to review the abrasion conditions and existing maintenance down time schedules.

By combining this with existing GET product performance data, CR Mining was able to recommend and then successfully trial the Super Penetrator (SP) Boxpoint GET product range which would deliver better performance in the conditions.

As part of the trial, CR used data from the Titan 3330 payload monitoring system which was already fitted to the excavator, to deliver real-time performance metrics on payload accuracy, operator variability and fleet efficiency with the new GET setup.

The TRS7031-RA Boxpoints were run for a 13 week period setting the baseline performance for the machine. TRS7030-SP Boxpoints were then run for an 18 week period on the same R996 machine using the same bucket in similar digging conditions for best comparable results.

Rock Abrasion (RA) vs Super Penetrator (SP) Boxpoint.

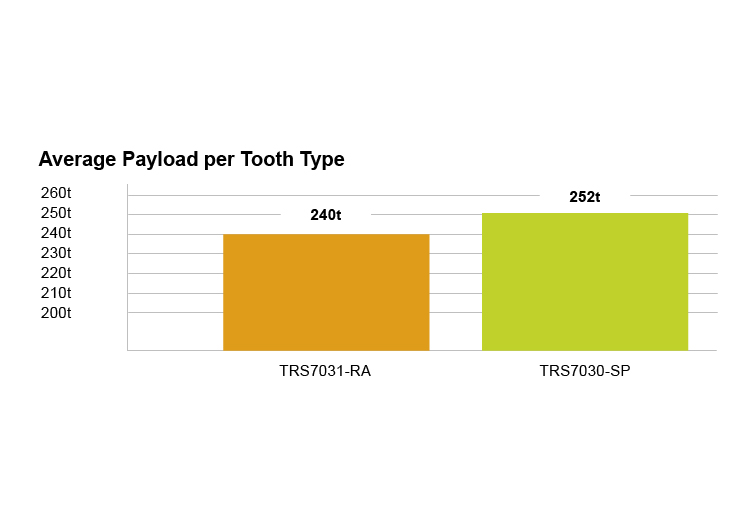

Average Payload per Tooth Type

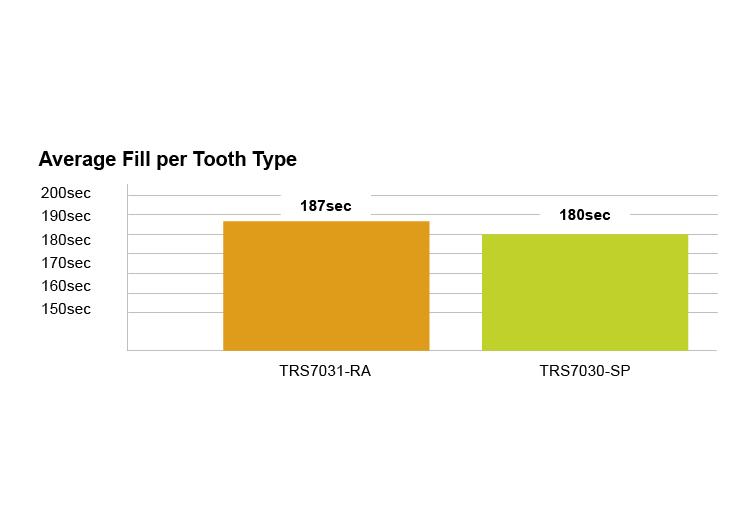

Average Fill per Tooth Type

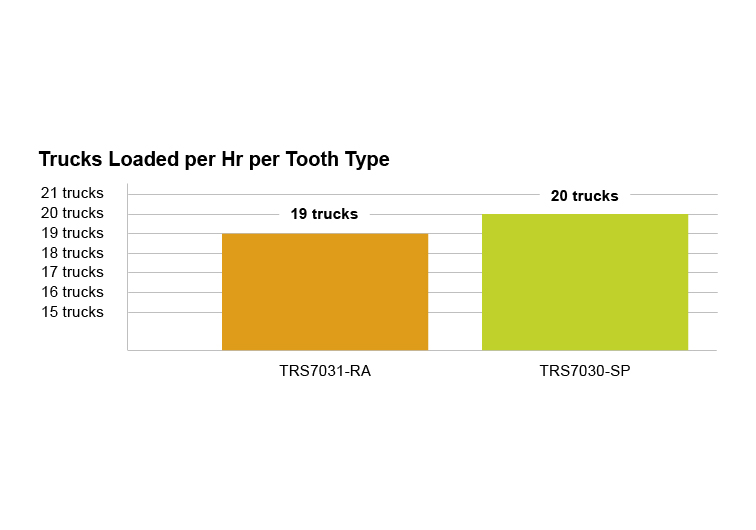

Trucks Loaded per hour per Tooth Type

The Impact

With CR expert advice and the optimized GET system, the Mine operator achieved outstanding productivity performance results including an increase on average of one truckload every hour.

The unique proprietary GET design maintained existing weight targets whilst ensuring the ground engagement profile would be optimized throughout service life.

- Achieved an additional 12-13 truck moves per day based on increased average production hours over the trial periods.

- Reduced truck fill time by an average of up to 7 seconds.

- Increased truck payloads by an average of up to 2.4%.

- Optimized material distribution for optimal wear characteristics in a backhoe application.

- Increased GET wear life, reducing machine down time

- Self-sharpening GET features delivered more effective penetration profiles results in the coal application.

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.