How CR’s GET Trakka is changing the Ground Engaging Tool Market

Ground Engaging Tools (GET) are now digitized, thanks to CR’s GET Trakka. Mine sites across the globe now have the opportunity to analyze and track GET across their operations with the new technology – aimed at providing operators with real-time data when it matters most. International Mining sat down with CR’s Head of Engineering and Innovation, Doug Wallis, to talk about the capabilities of this game-changing technology.

How does GET Trakka work?

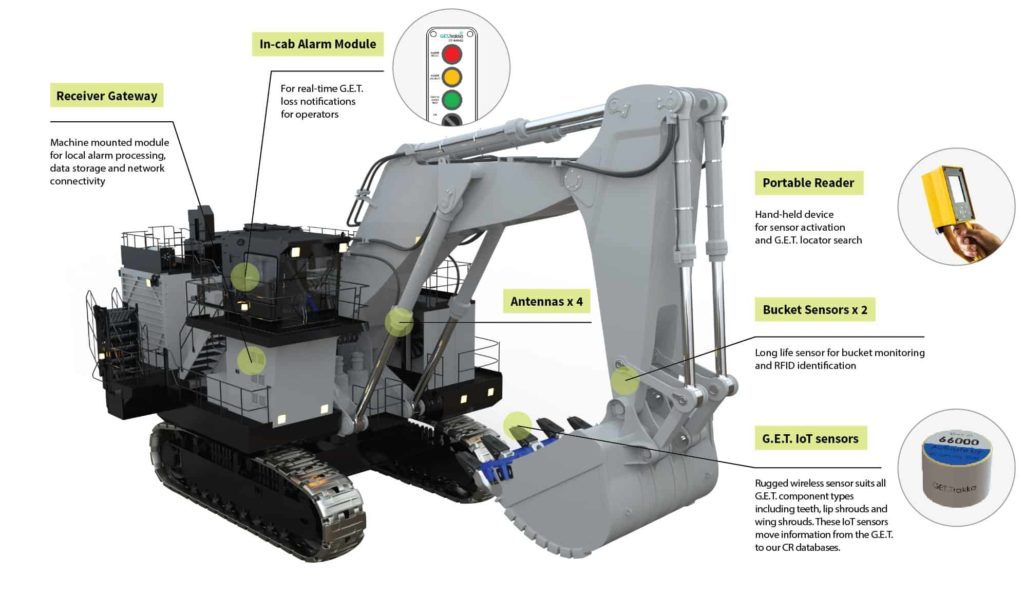

The GET Trakka solution includes a sensor inserted into excavator ground engaging tools and shrouds, combined with machine accessories including; bucket sensors, antennas, and an in-cab alarm module. The operator is immediately notified if a GET is lost, with the sensor allowing quick location identification. With real-time data, the GET Trakka helps prevent crusher down time events and improves safety across the operation. The sensor technology expands to extracting data analytics from each tooth helping develop insights into the wear life of the product in different commodities.

Q: Have your existing clients been calling out for a solution like GET Trakka when buying GET-related products from you in the past?

A: GET failure causes significant operational losses and potential safety risks for our customers and the industry has been looking for a reliable way of detecting GET failures and locating failed parts for years.

Q: How does the GET Trakka solution differ from other GET tracking products on the market?

A: Our product is the only proven GET sensor technology on the market. Competitors who offer machine-mounted systems that use technologies such as vision that rely on line of sight cannot offer the same functionality as CR because they are limited to what they can see from the machine rather than having a live sensor that is feeding data back to the user. This means that we are able to offer a much broader solution including for example the ability to locate and recover lost GET once they fall off the machine. Functionality such as this is essential for our customers to be able to easily recover GET and stop it from going into crushers. CR is uniquely positioned in the market in that we already have a range of complementary digital solutions that are sold through our CR Digital business. This means we can offer an integrated solution with much broader and more reliable functionality than our competitors.

Q: Is it the rugged embedded wireless sensors that differentiate it from other products on the market?

A: The rugged sensor does differentiate us. This sensor technology provides the foundation for us to offer a solution that is much broader and more reliable than anyone else.

How does GET Trakka improve mine operations?

Q: As well as notifying operators of actual tooth loss, does the solution ensure operators are aware of impending/potential tooth losses ahead of time?

A: The system today is primarily built to help customers detect a loss event when it occurs and to then locate the failed parts. Additionally, it also has the functionality to help customers better monitor and manage their GET including GET temperature, consumption rate, and wear life.

Q: What aspects of operational productivity are covered with GET Trakka?

This technology allows GET to be tracked from the time it is fitted onto a machine through to the end of life. Customers can therefore track when GET is fitted and removed, how long it lasts, how much material is moved, the live status of GET (such as temperature), and where it is. In other words, we’re able to get real-time live operational data on various aspects of GET and buckets.

Q: Have you got any evidence of GET Trakka improving mine site productivity?

A: The two areas where our customers see the biggest improvements are the reduction or elimination of lost time due to GET in crusher events and improved awareness and management of GET on their site. For example, one of our customers was experiencing GET in crusher events are regularly as once a month until they installed GET Trakka. With our system now in service on their site for several years, they have been able to effectively eliminate these events. GET failures still occur but they are now able to identify them and recover the GET from the dig face or truck before it gets into the crusher and causes any serious down time. This same customer is also using the operational data and reports that we provide to better understand and manage their GET usage and consumption and to give them early warning when GET is worn and nearing the end of life. For the case study in detail, contact the team today.

Future developments for CR

Q: What other aspects of GET maintenance are your R&D/business development teams now focused on?

A: We have a lot of very innovative and interesting R&D work underway that is focused on improving our GET solutions and making them smarter and safer. The GET Trakka acquisition is one example of a digital technology product that we are combining with our GET solutions to provide a smarter and more complete solution. This system will continue to be expanded to add more functionality and to integrate with some of our other digital and wear products. Along with this work we are also building a range of supporting tools and technology such as our recently released GRIPAssist that will help customers to manage and handle GET more safely and efficiently and ultimately reduce the amount of direct interaction that people need to have with our GET.