32 Million BCM Dump Block Campaign Life

Market-leading heavy-duty dump blocks achieve record campaign life for Bowen Basin coal miner.

Background

Location

Bowen Basin, QLD, Australia

Commodity

Coal

Digging Conditions

Overburden

Machine

Dragline

Make & Model

8200 Class

Rigging Configuration

Conventional Single-Dump

The Challenge

Draglines continue to be a critical element in hitting production targets for many coal mining operations. Reducing maintenance requirements is essential to increase up time, lower costs, and decrease safety risks. Dump rope change-outs are one regular maintenance task that can significantly impact machine up time and production.

The Solution

For over a decade, CR Powered by Epiroc’s heavy-duty dump blocks have set the industry standard for durability and long service life. Their robust bearing and axle assembly, optimized cast side plates, hardened sheave, and optimized rope groove profile all contribute to making them the most reliable dump blocks available today.

CR worked with the customer to upgrade their existing dump blocks and dump connecting link assembly from a traditional straight ear configuration to a high-performance twisted ear design.

The new configuration allows for more dump block side-to-side movement, improving dump rope tracking and connecting link wear.

The new sheave profile has been rolled out on all new CR dump blocks and is compatible with black rope. Combined with twisted-ear updates new blocks are also seeing a substantial improvement in dump rope life, allowing customers to space scheduled dump rope changes further out.

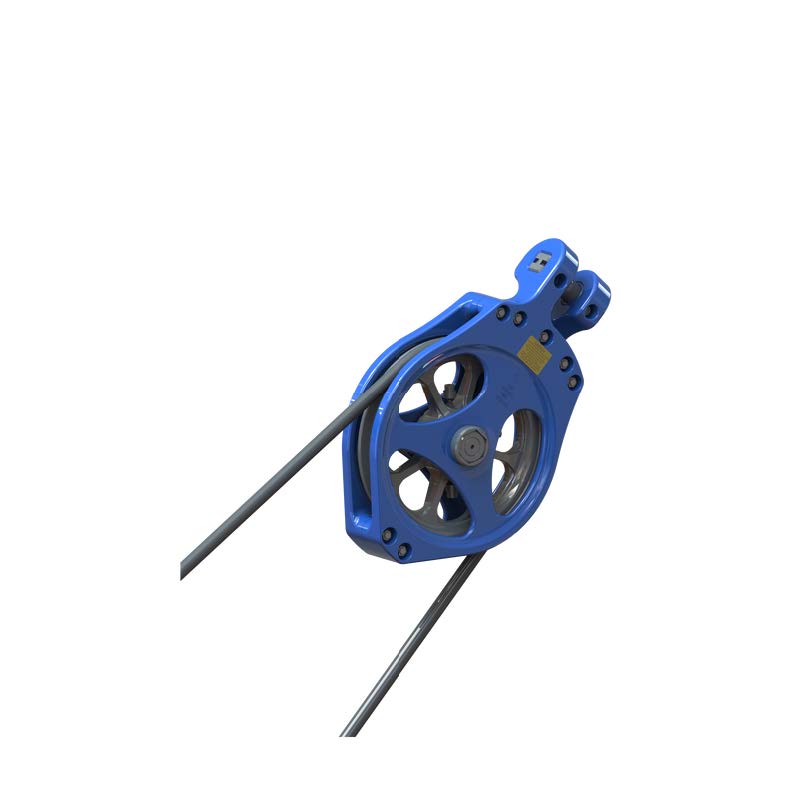

P48TW-83 Dump Block

The Outcome

Record campaign life

Less down time

Reduced costs

The Impact

The new dump blocks have achieved record-breaking campaign life, increasing campaign life from 18 million BCM to 32 million BCM, an increase of 77%.

As the dump rope life increased by 33%, the site was able to push out scheduled change outs from every seven days to a 9-10-9 day schedule. Not only did they save on maintenance down time, but the new schedule also aligned better with planned maintenance days, driving improved dragline availability.

Change out timing for dump connecting links has also been extended from every two months to every six. The result: saving approximately AU$37,000 per dragline each year.

All of this has added up to a significant reduction in maintenance time and labor for dump ropes and connecting links: approximately 300 man-hours each year.

- Campaign life of 32 million BCM, a 77% increase

- Dump rope life increased 33%

- Savings of ~AU$37,000 per year per dragline, a total of $185,000 across the fleet

- Reduced maintenance labor by ~300 man-hours per year

The mine site has been so pleased with the improvements that they have implemented CR’s twisted ear dump blocks on all five of their conventional draglines, resulting in a savings of AU$185,000 each year.

Explore More Success Stories

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.